【Instrument use】

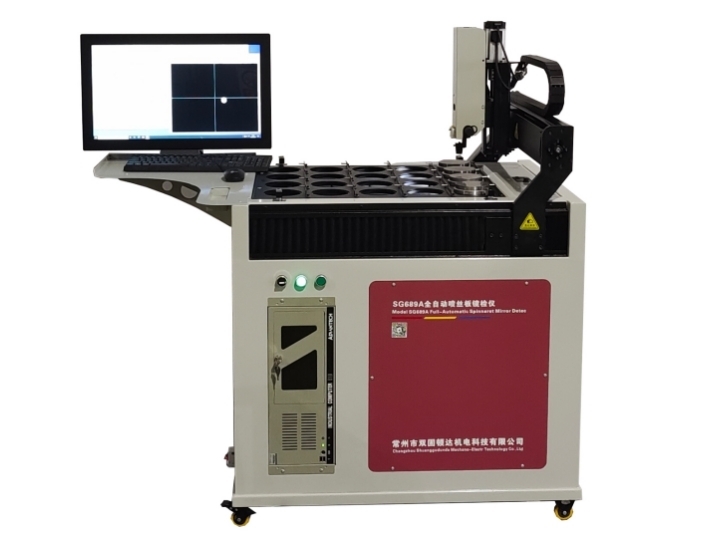

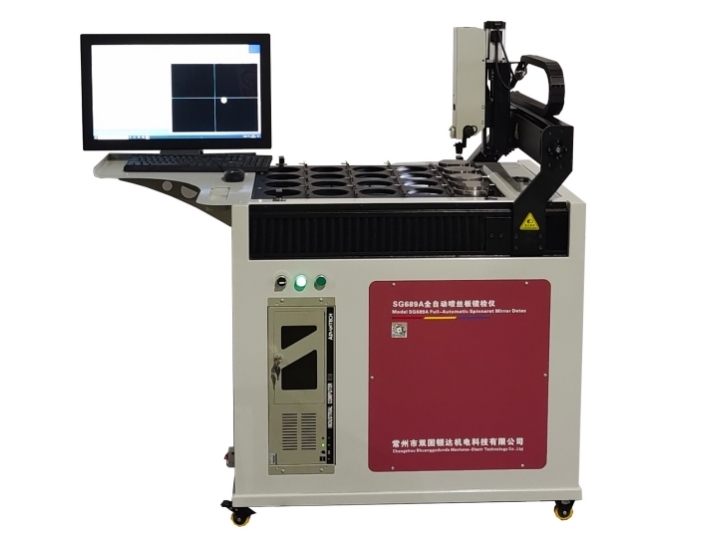

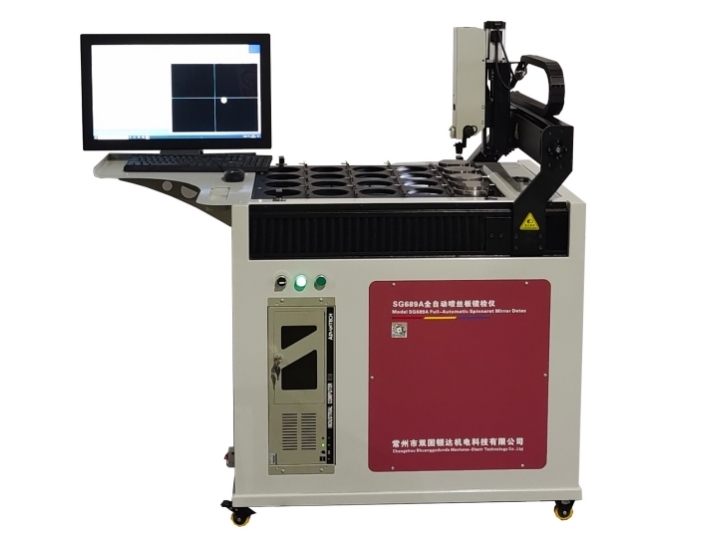

SG689A automatic spinneret mirror inspection instrument (detector) is used for automatic detection of chemical fiber filament spinnerets, staple fiber spinnerets, industrial yarn spinnerets of various shapes and specifications such as round, square, rectangle, etc. , Spinning plate, spinning mouth plate and other special testing instruments for the shape, size and blockage of die holes. According to the shape and size of the mold and the arrangement of the spinneret holes, the detection elements of any hole can be checked within the effective vertical and horizontal ranges.

【in summary】

① Introduction to the mechanical part

1. The SG689A automatic spinneret microscope adopts an automatic X-Y-Z three-axis motion control platform (that is, a three-axis orthogonal robot), and adopts an imported AC servo system for positioning. Each axis is equipped with a precision ball screw drive, sound Small, high precision, repeat positioning accuracy up to ±0.01mm.

2. The lens adopts high-pixel lens, which has the characteristics of small distortion and high resolution, and does not need to be replaced when selecting different magnifications.

3. The camera adopts a high frame rate and high resolution black and white industrial camera to ensure that the collected images are not distorted, thereby ensuring the measurement accuracy.

4. This machine adopts high-strength metal loading fixture and table, which has good load-bearing performance and is also convenient to replace the spinneret fixture. (Processed by a grinder to ensure flatness).

5. Equipped with a display, easy to observe the test process and progress.

② Introduction to the electrical part

1. Using a reliable image processing algorithm, it can detect the diameter, area, roundness, dirt rate and other parameters of the spinneret micro-hole (specific parameters are determined according to customer requirements), and automatically record the position of the unqualified micro-hole.

2. To calibrate the spinneret template file, the user can input the spinneret parameter settings by himself.

3. The lens realizes automatic focusing, which improves the detection efficiency.

4. The test data will be saved in the database, which is convenient for data recording and analysis.

5. Improve the detection rate of a single hole through the optimization of the algorithm and path, about 0.2-1s per hole, the detection rate will vary according to the specifications of the spinneret (the detection speed is directly related to the hole distance).

6. When testing different spinnerets, you only need to load different spinneret template files, and the operation is flexible and convenient.

7. The machine adopts Advantech original industrial control computer, the computer is equipped with X, Y, Z three-axis control and input and output card and adjustable light source controller, and is equipped with industrial control computer keyboard and mouse, and the data transmission is fast.

8. The machine adopts a long-life LED light source, which fully covers the spinneret loading fixture. The light source can pass through the spinneret micro-holes in all directions, so that it can be captured by the lens and displayed on the monitor to display a high-quality picture.

9. This machine adopts an all-in-one design, with a more beautiful appearance. It adopts high-strength metal loading fixtures and table tops, with good load-bearing performance and convenient replacement of spinneret fixtures.

③ Advantages of using this equipment

1. Guarantee the detection accuracy, avoid human factors such as missed detection and wrong detection, increase product quality, and avoid the generation of defective products.

2. Save labor costs and recover equipment costs in a short period of time: The detection system is fully automatic, and can truly detect each spinning hole without human interference. It works 24 hours a day, 365 days a year, which can reduce manpower The pressure of rising costs.

3. Quality inspection as a new spinneret entering the factory: Since this system measures the actual size of the spinning hole, through this system, the new spinneret can be inspected as an incoming inspection, and the size of the spinning hole of the spinneret can be known in advance to be correct. situation, to avoid installation and online in unknown circumstances, resulting in substandard products, resulting in deadweight loss.

4. Manage the actual data of the spinneret micro-holes in use, and provide data support for the refinement of production and the elimination of unqualified spinnerets.

5. Immediately evaluate and improve the abnormality of the spinning process: through this system, if the unclean holes of the spinneret are found to be concentrated in a certain area, it may be a temperature problem or other problems in a certain process during the spinning process, so as to improve the process.

【Technical indicators】

1. Save the data after each plate inspection is completed. If there is an abnormal situation, ensure that the spinneret data that has been inspected before will not be lost.

2. After the compressed air is connected, the spinneret can be cleaned by blowing air, and the seal mark or the light source positioning mark can be selected.

3. The consumable parts on the spinneret must be easy for customers to replace, and the replacement is easy

4. Provide a complete user guide after the equipment is completed (including precautions, daily maintenance of the equipment, common fault solutions, etc.)

【Detection method】

1 Using computer control and image processing technology, automatic hole-by-hole scanning detection, and record the test results.

2 For unqualified spinneret micro-holes, the instrument automatically records and can perform blow cleaning or seal marking functions, and can use a coaxial light source to indicate the position of unqualified holes after automatic cleaning.

【Definition of "full automation" of the microscope】

The "comprehensive physical examination" of all the spinneret holes is automatically completed by the microscope, that is, the "automatic" recording and inspection of the position coordinates of each hole, the record of the position coordinates of the abnormal holes, and the handle operation to blow air when cleaning the abnormal holes. Clean, still unqualified holes can be positioned by shining a coaxial light beam on the spinneret micro-holes.

【Test items】

1. Hole diameter, hole area, roundness, fouling rate, qualified micro-holes and other data, the test data shows "green" for spinneret holes within the qualified range, and "red" for unqualified ones. Judging the qualified quality of the micropores, whether the micropores are qualified, whether the micropore area is too large or too small, whether the detected micropore status conforms to the set range, and is marked with red or green.

2. The instrument program has a dual interface, a data interface and a graphical interface. The data interface can completely display the detection data of the micro-holes, and the graphical interface can intuitively see the real situation of the real-time inspection holes.

3. With the aperture measurement function, it can be used as the basis for the inspection of the spinneret, and the detected data of the spinneret can be directly saved in the computer.

【Main technical parameters of the instrument】:

1. Detection system

Detection area: 500mm (length) × 500mm (width), can be customized according to user requirements

Test table size: 850mm (length) × 700mm (width) × 1390mm (height), can be customized according to user requirements

2. One-piece design of electrical cabinet and host

3. Test items: micropore diameter, area, out-of-roundness rate, fouling rate, special-shaped hole size, etc.

4. Detection speed: 0.2-1 seconds/hole (detection speed depends on hole distance).

5. Detection accuracy: ±0.01mm.

6. The range of detectable micropores: 0.1mm-5mm.

7. The maximum number of spinnerets tested at one time: It depends on the specific size of the spinneret (for example, a maximum of 30 pieces can be placed with a diameter of φ88mm).

8. Motion control unit: three-axis robot, using 3 sets of servo motors and 3 ball screws.

9. Camera: 1.4 million pixel high-speed black and white camera, with little noise, little noise and no smear.

10. Light source: two upper and lower light sources are used, and different detection functions are realized by controlling the light source.

11 Lens: Imported continuous zoom lens, with small distortion and high detection accuracy.

12. Simplified Chinese detection software, supports customization of other languages (such as English, traditional Chinese, etc.).

Home

Home About Us

About Us News

News Product Center

Product Center Product catalog

Product catalog After-sale service

After-sale service Download Center

Download Center Customer case

Customer case Talent recruitment

Talent recruitment