Secret tremendous progress in yarn quality reasons

Information Sources: | Release date:

2016-06-21

| Pageviews:

Key words:

The past two decades, the level of quality rapid spinning of the yarn quality requirements are also rising. Pursuit of zero defect, unblemished production and improve internal and external quality of products, is the pursuit of quality and efficient modern enterprise combining production, it requires not only the yarn has a high intrinsic quality and appearance, but also to meet the high road after weaving production efficiency. Such as "lights out production, constantly weaving head," the mode of production on the yarn quality made high demands.

On the one hand to improve the quality of cotton yarn to enhance the level of quality provided the conditions, on the other hand raise the level of technology equipment and key equipment to enhance the quality of the yarn quality levels provide a guarantee. According to reports, in the past CJ14.6tex unevenness of less than 14% can be said is the industry's advanced level, and now has 11% of normal levels, a high level has reached 10%.

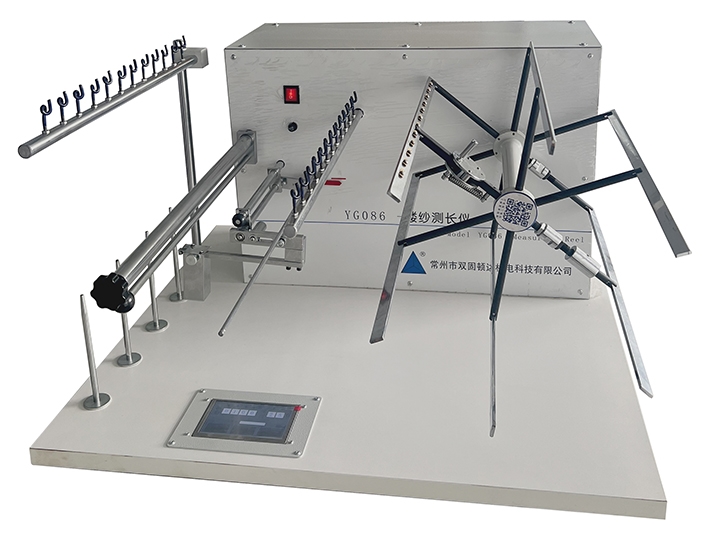

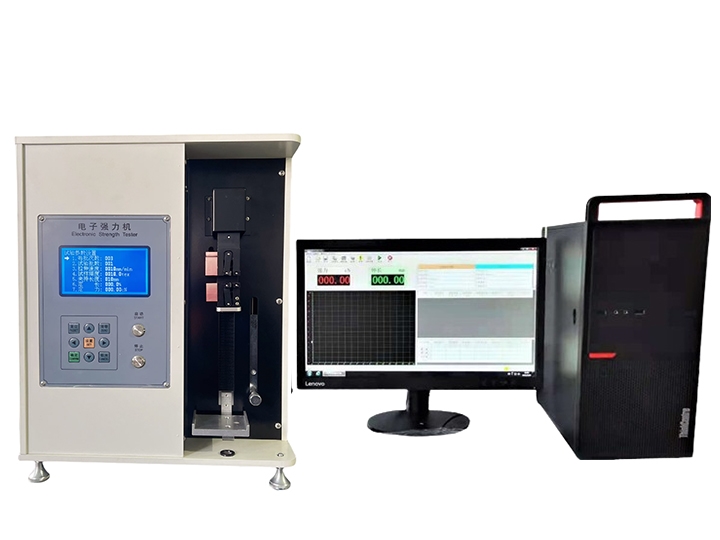

Today, the widely used optical, mechanical, electrical, pneumatic, hydraulic, and other sensor technology and variable frequency technology to promote the development of spinning technology to automation, intelligence, continuous direction, not only improves the production efficiency and labor productivity, but also for quality modern management methods, systematic, scientific creation of the conditions is the inevitable trend of development of textile production and quality management.

The use of online testing techniques to find the weak quality of the ring, to improve the quality of stability and consistency. With the development of the textile production automation, intelligent direction, the traditional off-line testing has been unable to adapt to the modern high-speed production. Offline test accounted for only one ten thousandth of the total product of the left and right, the detection level of quality does not accurately reflect the physical quality levels. Application of the full-line monitoring technology has become the trend of modern textile development. Online testing products 100% comprehensive testing, adjustment by detecting, monitoring, alarm and other means, can be defect or defective product to eliminate the production process. Online testing also has a quality analysis, statistics, product evaluation, and other functions, can detect, analyze and optimize production and effective combination for the production and quality control automation provide a guarantee. Online testing in production cost savings have certain advantages. Offline and online technology, can enhance the quality of yarn. The use of expert systems for quality control and optimization, improve the overall quality of management.

In the textile product quality testing process, the basic fabric of the cloth detection method using the full inspection, while the yarn quality inspection, as most testing is the use of destructive testing, which can only use random sampling. Spinning and weaving engineering works compared to its production unit that is more spinning spindles, random inspection, the quality is likely to have some defective spindles for a long time can not collect samples for testing, and a sub-sample level on behalf of the overall level of the average quality yarn and fabric quality can not be completely determined, often in the overall level is not bad batch of cotton yarn, the individual defective package will affect the overall quality of cloth and practical quality. Accelerate the development of online testing technology, the strengthening of the spinning process of production quality control, improve and perfect the deficiencies of traditional yarn quality detection methods to improve the level of quality textile products, is the direction of modern spinning production.

In addition, in the production of modern spinning systems, the machine faster and faster, fewer number of machines, the loss of quality defects appeared to reflect more. Therefore, each step warning pre-control is more important. At the same time, adjust the system from the spinning of raw materials needed from the system to the extent of controlled quality inspection, the impact of raw materials through various performance yarn quality to pre-control spinning mass production trends.

Home

Home About Us

About Us News

News Product Center

Product Center Product catalog

Product catalog After-sale service

After-sale service Download Center

Download Center Customer case

Customer case Talent recruitment

Talent recruitment