Meltblown cloth oiliness testing instrument testing equipment

Information Sources:本站 | Release date:

2020-11-25

| Pageviews:

Key words:Meltblown cloth oiliness testing instrument testing equipment

The United States NIOSH (National Institute of Occupational Safety and Health) organization divides mask filter materials into the following three types according to the lipophilicity of the material:

1. N series: N stands for Not resistant to oil, which can be used to protect non-oily suspended particles without time limit.

2. R series: R stands for Resistant to oil, which can be used to protect non-oily suspended particles and sweat-oily suspended particles. The time limit is eight hours.

3. P series: P stands for oil Proof, which can be used to protect non-oily suspended particles and sweat-oily suspended particles without time limit. When the carrier of some particulate matter is oily, and these substances attached to the electrostatic non-woven fabric will reduce the electrical properties and allow the fine dust to penetrate. Therefore, the anti-aerosol-containing filter material must undergo special electrostatic treatment to prevent fineness. The purpose of dust.

European Union EN149 standard FFP1: Minimum filtering effect>80% FFP2: Minimum filtering effect>94% FFP3: Minimum filtering effect>97%.

The European standard is certified by the European Commission for Standardization (Comité Européen de Normalisation, CEN) for respiratory protective equipment. The standard is to divide the particulate protection filter material into solid particle protection and liquid particle protection, which are tested and classified by NaCL (sodium chloride) and DOP (paraffin oil) aerosols respectively. Qualified solid particle protection filters are classified into P1 (FFP1), P2 (FFP2) and P3 (FFP3) according to the tested particle penetration rate. Among them, P3 has the best protection performance and P1 has the lowest protection performance. The liquid particle protection filter material is divided into two levels, P2 and P3, and the protection performance of P3 is higher than that of P2. The difference from the American standard is that its detection flow rate is 95L/min and DOP oil is used to generate dust.

In addition, NIOSH divides each type of filter material into 95 (95%), 99 (99%), 100 (99.97%) three types according to the filtration efficiency, so that each of the three types of materials has three filtration efficiency, so there are a total of nine grades. Masks. N95 mask①, R95 mask, P95 mask with 95% filtration efficiency; N99 mask, R99 mask, P99 mask with filtration efficiency 99%;

The filtration efficiency is 99.97% N100 mask, R100 mask, P100 mask.

N-grade products are mostly American standards, the melt blown cloth used for N95 is generally 40-50g/m2, and the product used for N99 is 70-80g/m2 or more than 80g. P grade products are European standard, the melt blown cloth used for P1 is generally 30-35g, P2 is 40-50g, and P3 is about 80g.

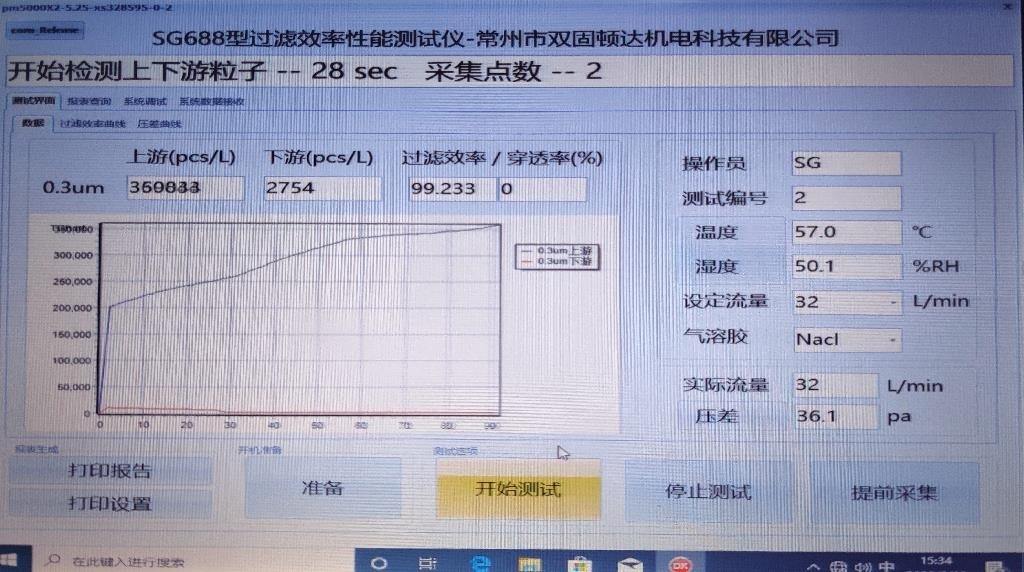

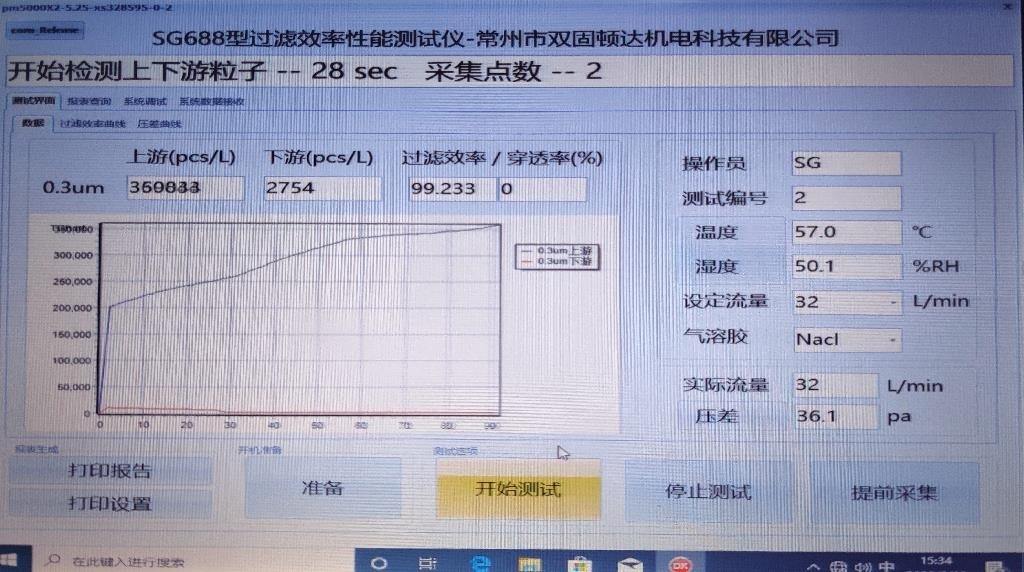

Meltblown cloth oiliness testing instrument testing equipment recommends Changzhou Shuanggu Dunda Electromechanical Technology Co., Ltd. independently produces SG688 filtration efficiency performance tester, with a test flow rate of 95L/min, testing aerosol oily particles (such as DESH, DOP and other oily liquids).

Product Usage:

SG688 melt blown cloth filtration efficiency performance tester is used to test the filtration efficiency of melt blown cloth, daily protective masks, medical masks, and respirators for particulate matter.

Features:

1. Equipped with a laser dust particle counting sensor to measure the number of aerosol particles in the upstream and downstream of the filter material at the same time, and accurately measure the filtration efficiency of the filter material.

2. Equipped with an aerosol generator to measure the filtration efficiency of particulate matter to meet users' testing requirements for filter materials.

3. Equipped with aerosol and neutralizing gas flow meters to control the number of salt particles in aerosols,

4. Equipped with a high-voltage anti-static air nozzle for neutralizing static electricity in aerosols.

5. The gas that neutralizes the aerosol concentration is heated to 35 degrees and then mixed and transported to the upstream of the filter material.

6. Equipped with a high-precision digital flow sensor for measuring the gas flow during testing.

7. High-precision differential pressure transmitter to test the airflow resistance on both sides of the sample.

8. Use a vacuum pump to generate the negative pressure required for testing, quiet and no vibration.

9. The upstream and downstream aerosols are discharged into the air after passing through the filter to prevent the air near the instrument from being polluted.

10. Equipped with 14-inch display, industrial computer operating software and control hardware.

11. Pneumatic clamps hold the samples, and have a mechanical anti-pinch design to prevent operating errors and ensure safety.

12. The computer comes standard with a micro printer to output test reports.

13. The electrical connection is safe and reliable to protect the safety of operators and instruments.

According to the standard:

GB 2626-2019 "Respiratory protective equipment self-priming filter anti-particulate respirator" (salt aerosol)

GB/T 32610-2016 "Appendix A to Technical Specifications for Daily Protective Masks" (salt aerosol)

GB 19083-2010 "Technical requirements for medical protective masks" (salt aerosol)

YY0469-2011 medical surgical mask

Test content:

Filter efficiency% and air flow resistance test (GB 19083-2010)

Equipment technical parameters:

1. Air flow adjustment and collection range: 20-100L/min, flow can be adjusted and collected within the range of 20-100L/min, accuracy 1%FS

2. Filter efficiency test range: (0.001-99.999)%, resolution 0.001%.

3. Test area: 100cm² (KN95 mask tooling fixture is optional)

4. Ventilation resistance: 0-1000pa, accuracy 1pa

5. Aerosol: saline equipment

6. Aerosol concentration: the concentration of NaCl aerosol generator does not exceed 200mg/m³, the median diameter of counting is (0.075±0.020)um, the geometric deviation of particle size distribution does not exceed 1.86, and the mass median diameter is about 0.3um.

7. Laser dust particle counting sensor test channel: 6 channels, which can measure the number of particles with diameters of 0.3μm, 0.5μm, 1.0μm, 2.5μm, 5.0μm and 10.0μm.

8. Power: about 800w

9. Product size: length * width * height (720mm *620mm *1420mm)

10. Weight: about 160 kg

Customers need to provide the following contents:

①Compressed air source

The compressed air pressure is 0.5~0.7MPa, the flow is greater than 0.3m³/min, and the compressed air is required to be dry and clean.

②Power supply

220VAC, 50Hz; stable power supply above 1.5kW (grounding wire is required).

③ Sufficient venue space: 3M (length) X3M (width) X1.8M (height).

Home

Home About Us

About Us News

News Product Center

Product Center Product catalog

Product catalog After-sale service

After-sale service Download Center

Download Center Customer case

Customer case Talent recruitment

Talent recruitment