SG710 Loss-in-weight masterbatch feeder

Key words:SG710 Loss-in-weight masterbatch feeder

Product Description:This equipment is a metering system specially developed for precise feeding control and management in the chemical fiber industry. Mainly used in polyester yarn spinning, polypropylene yarn spinning, nylon yarn spinning, civil yarn, industrial yarn, differ…

This equipment is a metering system specially developed for precise feeding control and management in the chemical fiber industry. Mainly used in polyester yarn spinning, polypropylene yarn spinning, nylon yarn spinning, civil yarn, industrial yarn, differentiated fiber and other functional fiber production processes where masterbatch needs to be added.

The main technical parameters

Flow measurement method: loss-in-weight measurement

Unloading method: continuous unloading

Hopper volume: customizable

Applicable logistics types: non-sticky particles or powder

Features:

1. Can realize remote monitoring

2. Network interoperability (customized)

3. Data can be saved, making it easier to manage product quality

4. Abnormal alarm to prevent misoperation

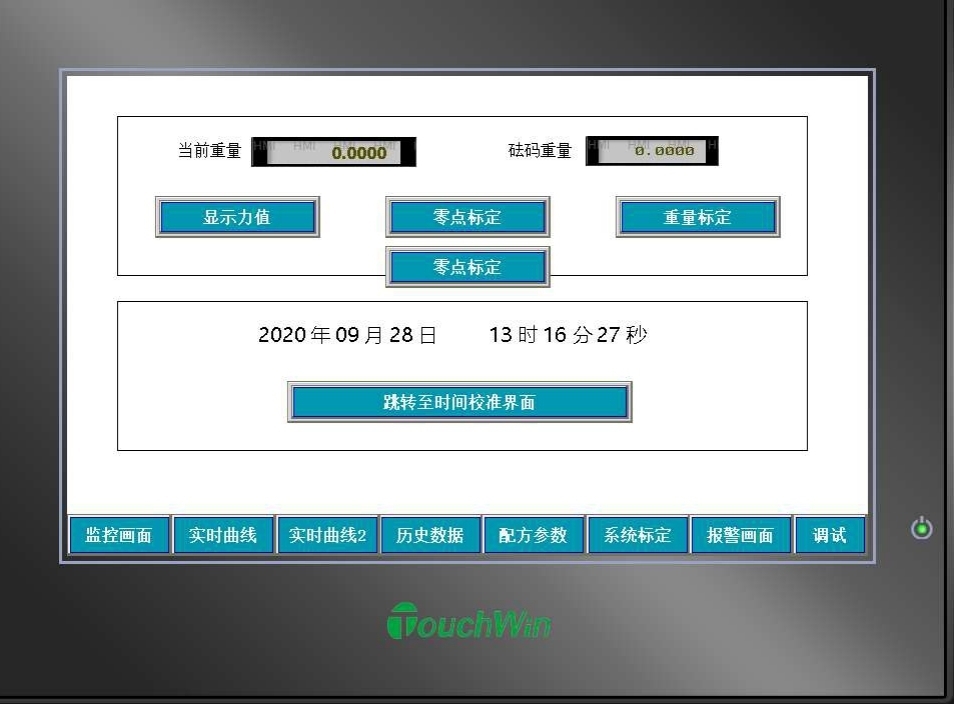

5. Users can calibrate themselves

6. The management interface is separated from the user interface, and a password is required to enter the management interface to prevent misoperation by the user

|

part

|

Standard

|

Upgrade

|

|

Weighing module

|

AVIC

|

Mettler Toledo

|

|

PLC

|

Wuxi Xinje

|

Siemens

|

|

Case

|

Double solid homemade

|

Double solid homemade

|

|

buzzer

|

Configuration

|

Configuration

|

|

Host

|

Double solid homemade

|

Double solid homemade

|

|

Device model

|

Flow setting

g/h

|

Measurement method

|

Precision

F.S

|

Hopper capacity

L

|

Feeding method

|

Screw type

|

Motor Power

|

|

SG710

|

200-2100

|

Weighing

|

≤0.5

|

7

|

Continuous feeding

|

Small screw

|

400w

|

|

SG710

|

1500-5000

|

Weighing

|

≤0.5

|

7

|

Continuous feeding

|

Middle screw

|

400w

|

|

SG710

|

4000-12000

|

Weighing

|

≤0.5

|

7

|

Continuous feeding

|

Big screw

|

400w

|

Instrument characteristics

(1) A masterbatch injection machine is used to change the traditional manual feeding method and realize automatic feeding. The processing effect is more excellent, and the uniformity and accuracy of the produced products are improved. It is a necessary product for enterprises to achieve high efficiency, high quality and automation.

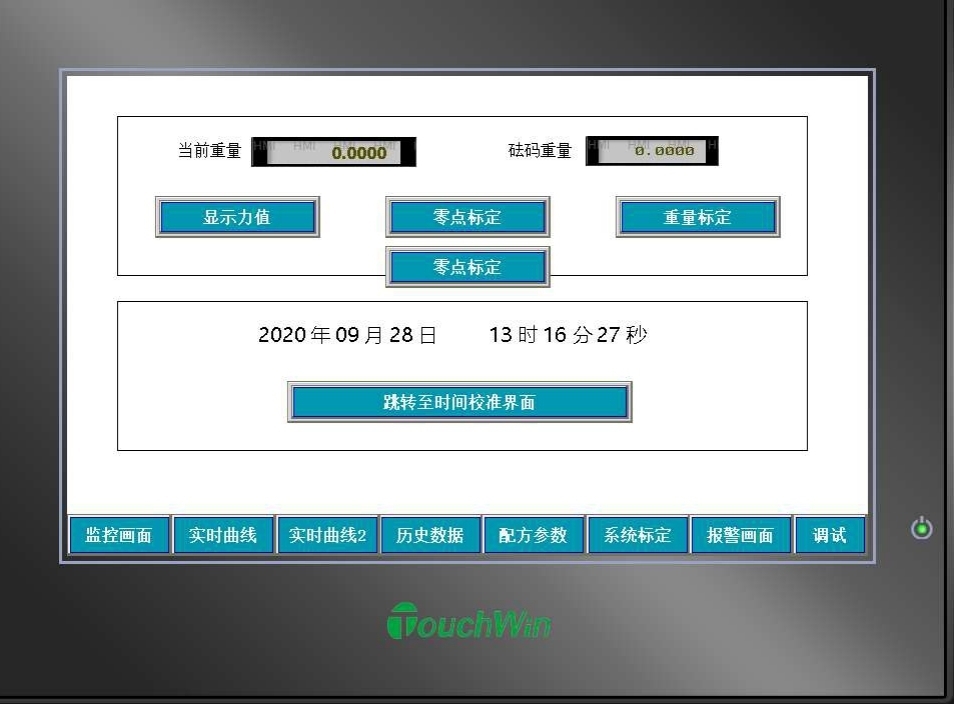

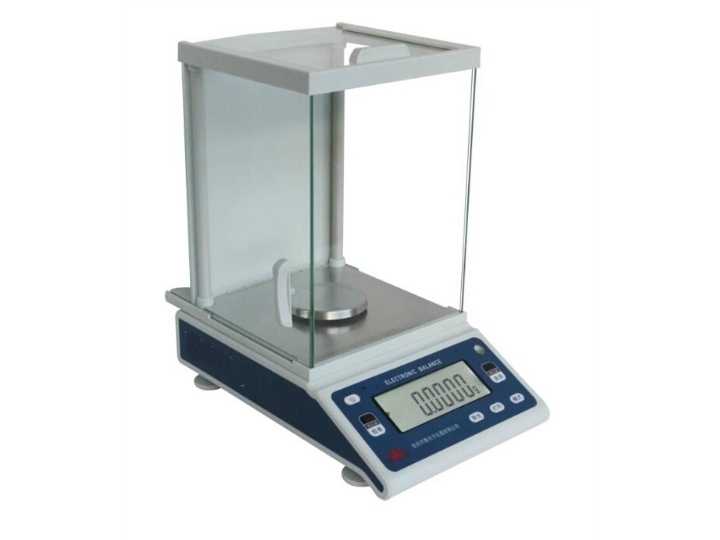

(2) There is a high-precision weighing module inside the masterbatch injection machine (using the domestic military enterprise sensor: AVIC), which can accurately control the material consumption and feeding speed through real-time weighing. The effective control of the measurement value has greatly improved the quality of the finished product, while also reducing the probability of occurrence of defective products.

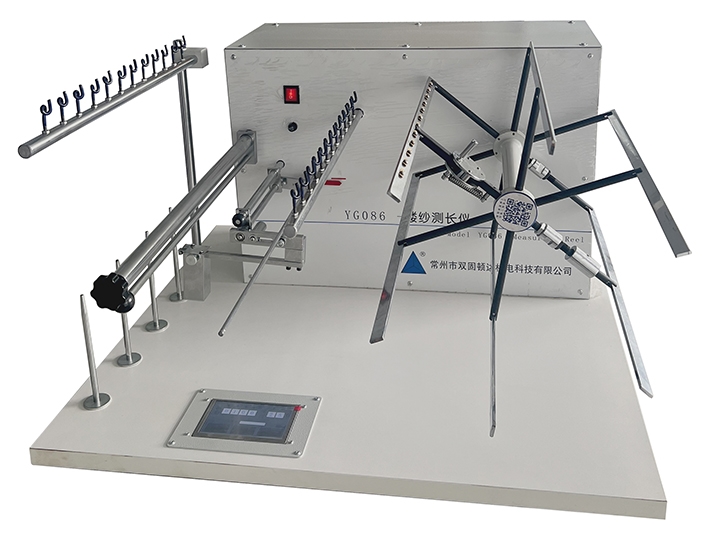

(3) The weightless masterbatch injection machine adopts an adjustable and assembled structure design, which can save a lot of trouble in the process of installation, disassembly and maintenance, and provide users with a good experience.

(4) It adopts plc control, has good anti-interference, humanized interface, detailed and accurate digital display on the display, and easy operation. The user can remotely control the output and measurement of the masterbatch injection machine through the control panel or electronic equipment for real-time monitoring.

(5) It is convenient and simple to replace materials, which is convenient for cleaning and cleaning. In the later maintenance process, through the combined detachable design of the masterbatch injection machine, targeted maintenance work is carried out with high efficiency.

(6) Modular design, it can be used as a loss-in-weight feeder or as a volumetric feeder.

(7) Using AC servo motor, small size, low vibration, stable performance, high control precision, good torque-frequency characteristics to achieve fast and accurate measurement.

(8) Using planetary reducer, there is no gap during operation

(9) Equipped with anti-vibration pads to ensure smooth and stable operation.

(10) High-performance operability: The entire feeder is easily disassembled and designed to facilitate rapid cleaning of the feeder;

(11) The masterbatch machine adopts microcomputer control, intelligent and accurate calculation

(12) Equipped with three different sizes of screws, it is convenient to use different screws with different flow rates and different materials.

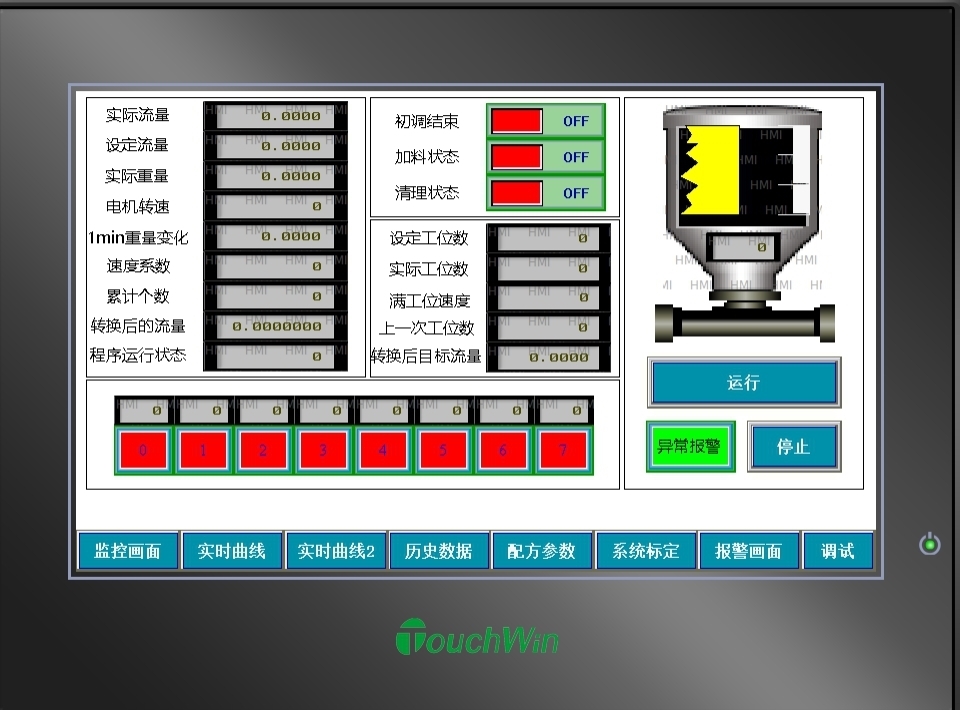

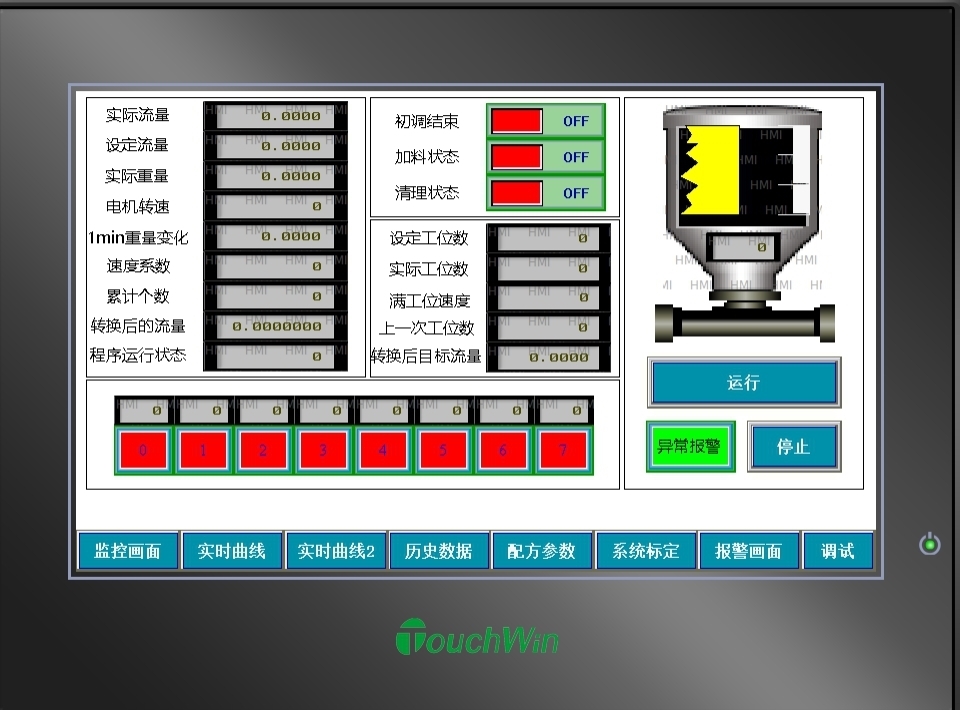

SG710型色母粒注射器主界面

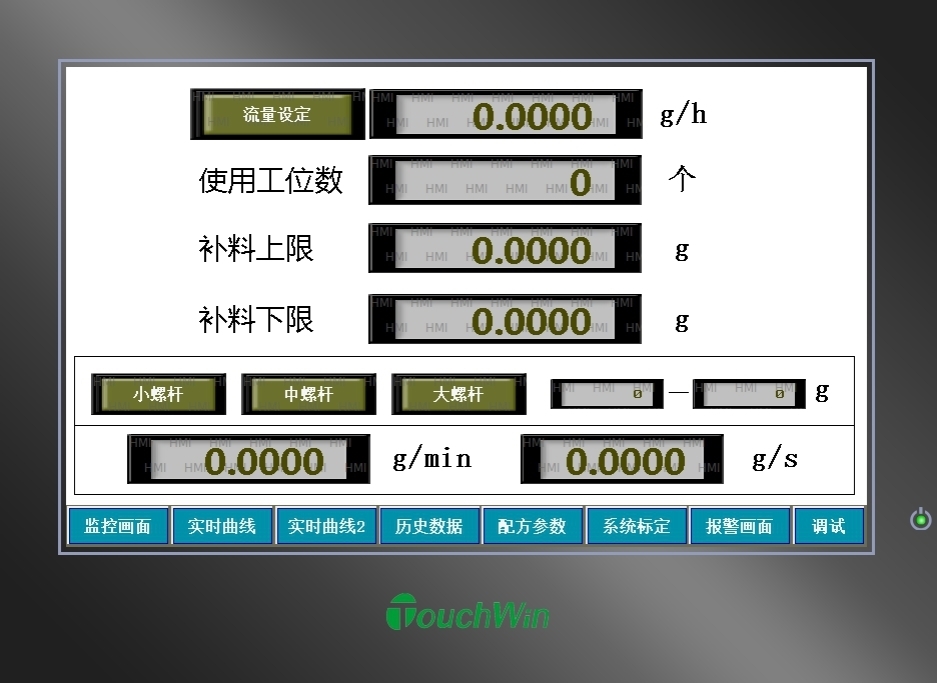

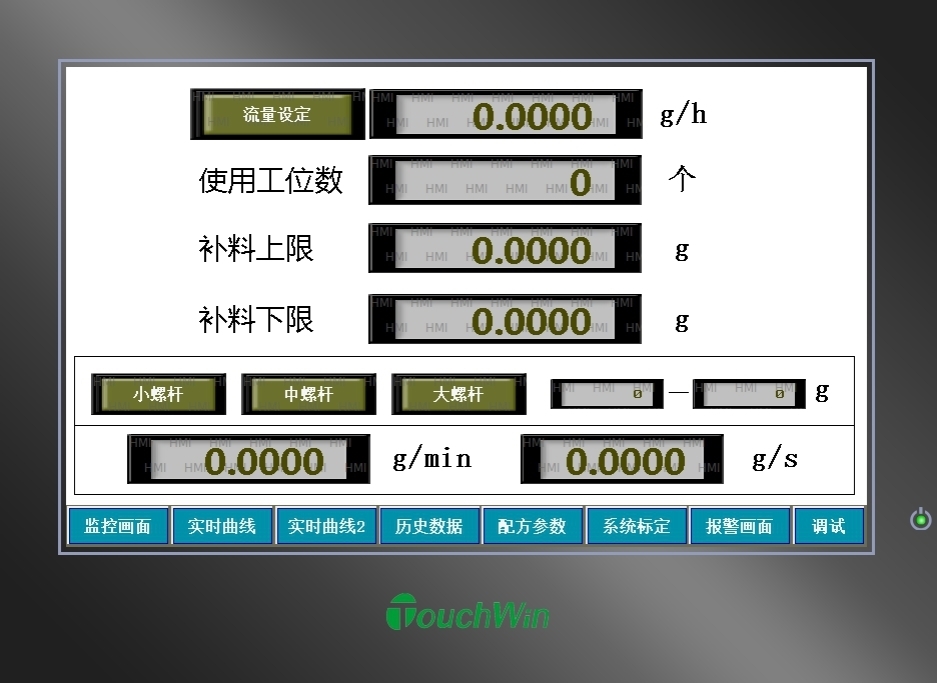

流量及参数设定界面

Home

Home About Us

About Us News

News Product Center

Product Center Product catalog

Product catalog After-sale service

After-sale service Download Center

Download Center Customer case

Customer case Talent recruitment

Talent recruitment