SG689WF Fully Automatic Non woven Spinning Board Inspection Instrument (Inspection Instrument)

Key words:SG689WF Fully Automatic Non woven Spinning Board Inspection Instrument (Inspection Instrument)

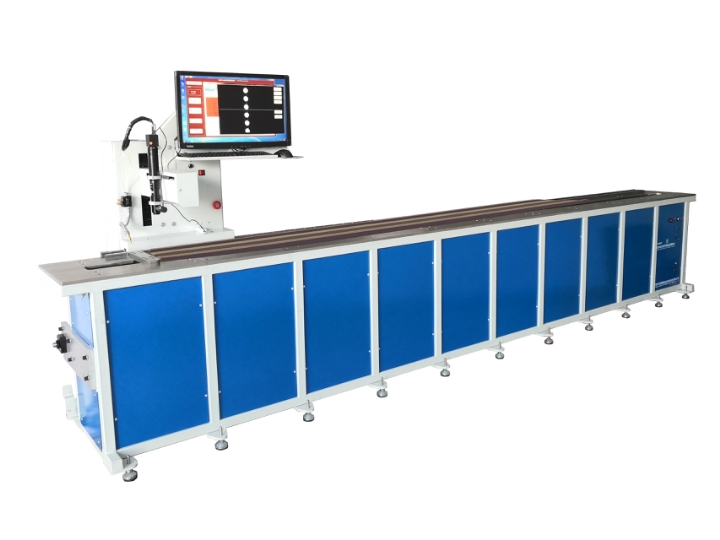

Product Description:Scope of application of the instrument: The SG689WF fully automatic non-woven spinneret mirror inspection instrument is suitable for detecting micropores in non-woven spinnerets such as 1.6-meter, 2.4-meter, 3.2-meter meltblown, spunbond spinnerets, and wa…

Scope of application of the instrument: The SG689WF fully automatic non-woven spinneret mirror inspection instrument is suitable for detecting micropores in non-woven spinnerets such as 1.6-meter, 2.4-meter, 3.2-meter meltblown, spunbond spinnerets, and water needle spinnerets.

[Instrument Overview]

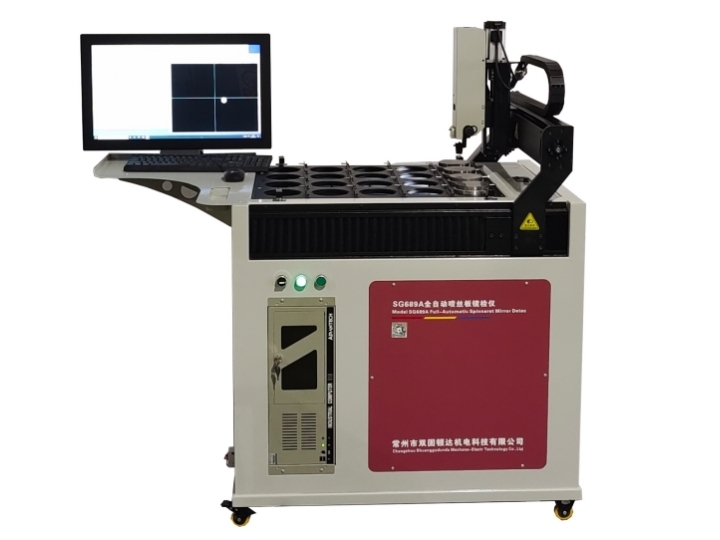

a. The SG689WF fully automatic non-woven spinning plate mirror inspection instrument is mainly composed of a computer, a motion control system, and an image acquisition system. It automatically measures the micropores of the non-woven spinning plate and can completely replace manual operation. It can truly detect micropores and detect the hole area (whether the micropores are blocked), hole area, hole circumference and other indicators of the non-woven spinning plate. Detailed measurements of micropores in each area are carried out by region, and the test data can be saved and printed out at any time.

Introduction to Fully Automatic Non woven Spinning Board Mirror Inspection Instrument

① Hardware Introduction

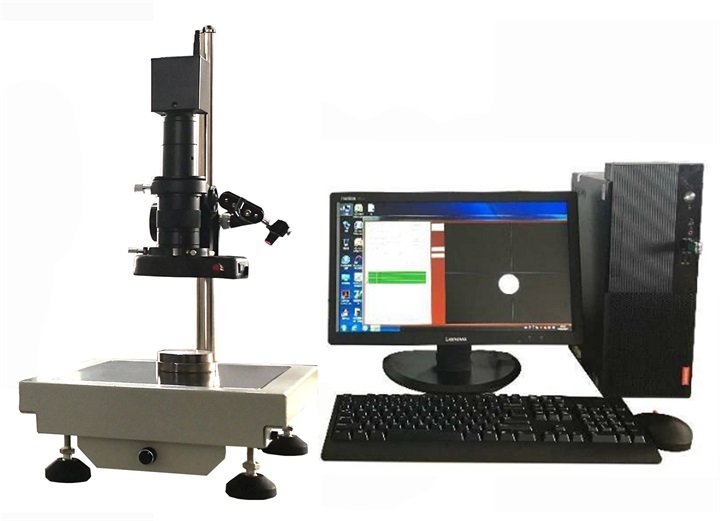

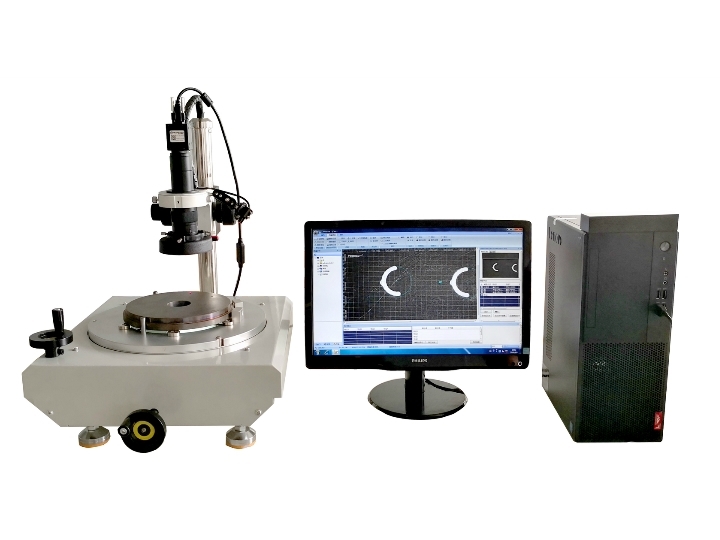

1. Adopting a fully automatic X-Y-Z three-axis motion control platform (i.e. three-axis orthogonal robot), using servo motors for positioning, the repeated positioning accuracy can reach+-0.01mm.

2. The lens adopts a continuous zoom lens, which has the characteristics of low distortion and high resolution

3. The camera adopts a high frame rate and high-resolution camera to ensure that the captured images are not distorted, thereby ensuring measurement accuracy.

4. Use a constant LED light source to ensure that the testing environment is not affected by external light sources.

5. The overall framework adopts a metal frame (the work platform adopts a whole thick aluminum plate to ensure the flatness of the platform).

6. Equipped with a monitor for easy observation of the testing process and progress (the monitor is directly installed on the device to save space).

7. Use branded computers to ensure hardware stability.

① Software Introduction

1. By using reliable image processing algorithms, it is possible to detect parameters such as the area and circumference of micro holes in non-woven spinnerets (specific parameters depend on the specific hole type), and automatically identify and clean up unqualified micro holes.

When calibrating the template file of the spinneret, the hole coordinates are automatically collected for easy operation. The order of hole detection can be customized or optimized by software (automatic optimization can reduce detection paths and improve detection efficiency).

3. The lens achieves automatic focusing to improve detection efficiency.

4. It has the function of detecting the parallelism between the lens and the fixture, and between the lens and the non-woven fabric spinneret, which facilitates mechanical debugging.

5. The test data will be saved in the database and can be printed or saved in reports for easy data recording and analysis.

6. Improve the efficiency of micro hole detection on the spinneret through algorithm and path optimization.

When detecting different non-woven spinnerets, only different non-woven spinneret template files need to be loaded, making the operation flexible and convenient.

② Advantages of using this device

1. Ensure detection accuracy, avoid human factors such as missed or false detections, increase product quality, and prevent the occurrence of substandard products.

2. Save manpower expenses. Due to the fully automated process, one person can complete the inspection of multiple boards. As it is a mechanical equipment, it can work continuously 24 hours a day, further reducing costs.

When purchasing a new non-woven spinning board, its quality can be inspected through this equipment.

4. Master the service life and quality of old non-woven spinning boards.

Main technical parameters of the instrument

1. The size of the detection system can be customized according to customer requirements. Taking a 3.2-meter spinneret as an example, the reference size for customization is 4450mm × 770mm × 1380mm (length × width × height). The weight of the detection system is approximately 690 kilograms

2. Computer monitor and host integrated design

3. Testing items: micropore diameter, area, perimeter, fouling rate, roundness loss rate, micropore qualification status, etc

4. Detection type: Single hole/area detection of non-woven spinneret micropores (depending on the spinneret)

5. Detection accuracy: ± 0.01mm.

6. The range of detectable micropores is 0.05mm-5mm.

7. Types of spinneret fixtures: customizable to 1.6 meters, 2.4 meters, 3.2 meters and other specifications (can be customized according to customer requirements)

8. Motion control unit: adopting X-Y-Z three-axis motion control platform, using 3 sets of servo motors and 3 ball screws

9. Camera: High pixel industrial camera, capturing images without distortion, low noise, and high measurement data accuracy

10. Light source: Two light sources are used, and different detection functions are achieved by controlling the light sources.

11. Lens: Adopting a continuous zoom lens with low distortion and high detection accuracy.

12. Simplified Chinese detection software, supporting customization of other languages (such as English, Traditional Chinese, etc.)

13. Configure a blowing cleaning device

Home

Home About Us

About Us News

News Product Center

Product Center Product catalog

Product catalog After-sale service

After-sale service Download Center

Download Center Customer case

Customer case Talent recruitment

Talent recruitment