[Scope of Application]

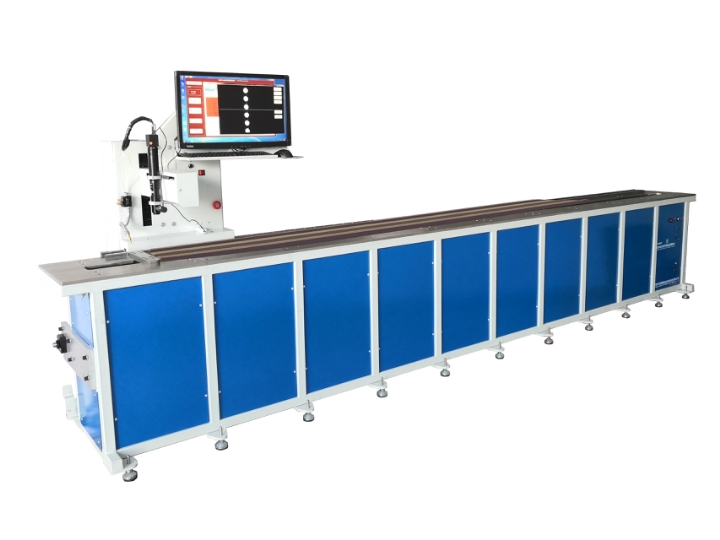

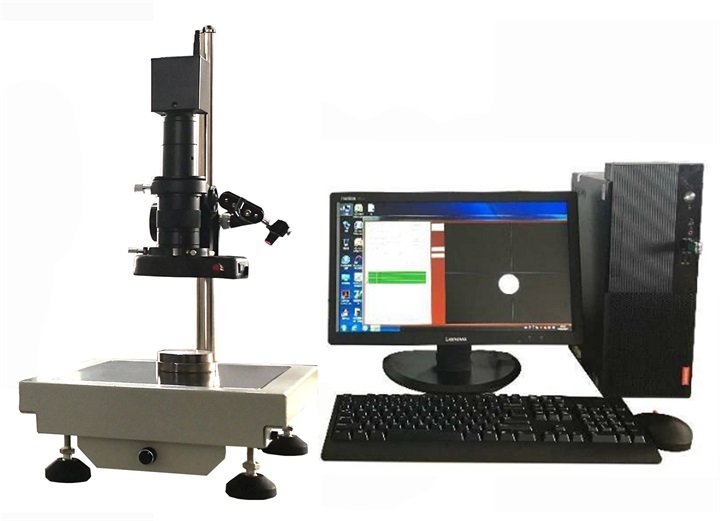

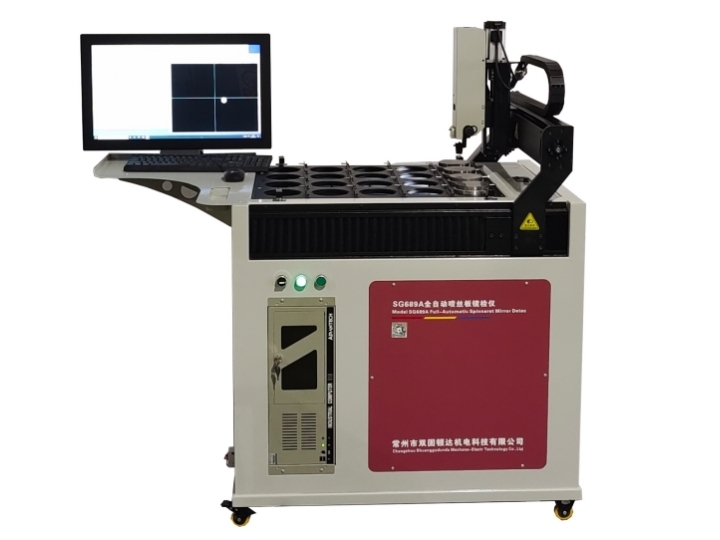

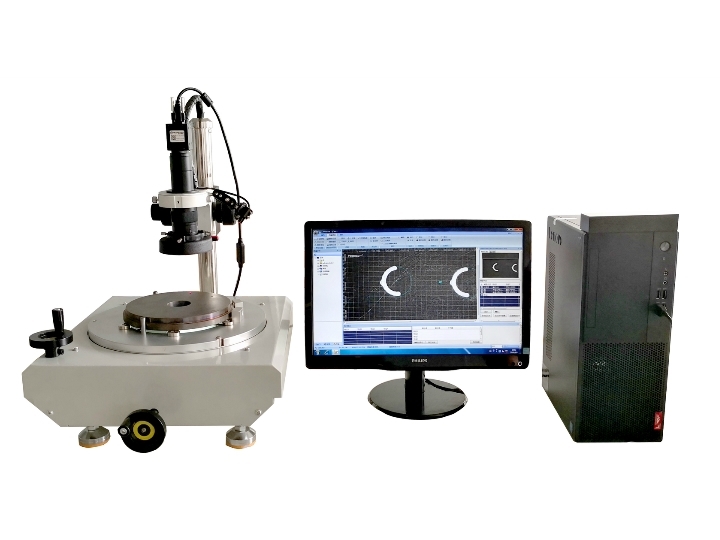

The SG689XK inclined hole spray plate manual mirror inspection instrument is mainly used in domestic chemical fiber production plants and spray plate manufacturing plants to test the qualified performance of composite spinning inclined hole spray plates and sea island distribution plates. It can detect a single spray plate with a circumferential or arbitrary distribution, and can be optionally equipped with a computer with inspection software. It can accurately quantify the key parameters of micro holes on the spray plate and objectively judge the cleanliness of micro holes, effectively reducing manual misjudgment and improving the detection efficiency and machine qualification rate of spray plates.

Technical indicators

1. Lens: Main objective lens 0.7-4.5X continuous zoom high-definition lens with laser positioning

2. Magnification ratio 1:6.5

3. Working distance: 100mm

4. Handwheel focusing range: 40mm

5. Range of lifting adjustment (column): 110mm

6. Lighting: Input voltage: 220, output: 12V

7. Image display section: The image is displayed in high-definition magnification on the Lenovo monitor.

8. High definition industrial camera CCD (no ghosting when moving)

9. Micro hole detection range 0.1-1.5mm

The device configuration is as follows:

1. SG689XK inclined hole spray coating plate manual mirror inspection machine host 1 unit

2. Customized fixture for spinneret (size range can be customized according to the customer's spinneret specifications)

3. One set of X and Y axis moving operation slide table (customized according to the shape and size of the spinneret)

①. X. The Y-rail and circumferential direction run smoothly and lightly throughout the entire process.

②. X. Clear imaging within the full range of movement in the Y rail direction.

③ 360 ° rotation in the circumferential direction (applicable to concentric circular spinnerets) ④ The X direction is manually moved.

4. 2 cameras

5. 2 lenses (same laser positioning)

6. Data connection cable: 1 piece

7. Lenovo computer+monitor: 1 set

8. Independently developed software: 1 set (capable of simultaneously observing images from two cameras on one screen)

9. Positioning electric light source: Input voltage: 220V

10. Configure 1 set of concentric circle fixtures to facilitate the rotation of concentric circle distribution spinnerets (customized, suitable for concentric circle distribution spinnerets)

11. Temperature range: 10-50 ℃

Home

Home About Us

About Us News

News Product Center

Product Center Product catalog

Product catalog After-sale service

After-sale service Download Center

Download Center Customer case

Customer case Talent recruitment

Talent recruitment