[Purpose]

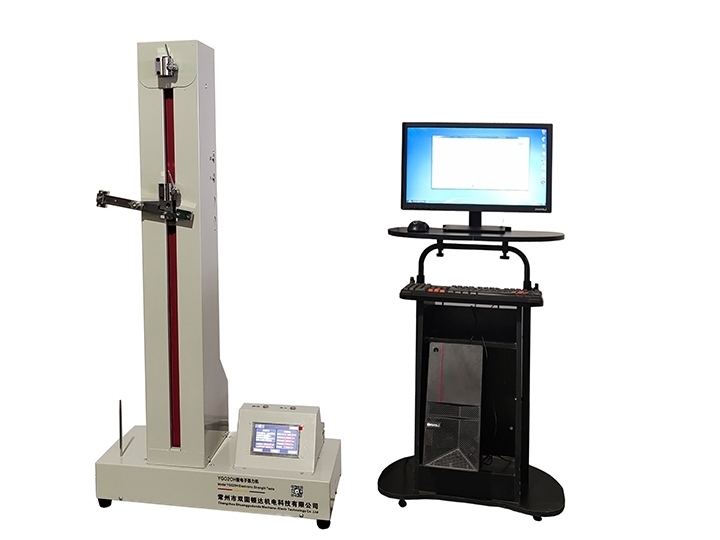

The YG026T electronic sling tensile machine can be used to measure the breaking strength, elongation, strength, constant load elongation, constant elongation load and other testing indicators of lifting belts, ton bags, container bags, safety belts, webbing, geotextiles, plastic woven bag base fabrics, plastic flat wires and other products by configuring different range sensors and testing fixtures. The equipment needs to be connected to a computer for operation, and users can choose to use their own computer or a manufacturer's matching computer for operation.

[Applicable Standards]

GB/T 10454, GB/T 6096, GB/T 3923.1, GB/T 9774, GB/T 8946, GB/T 8947, QB/T 4912, Appendix A of GB/T8946, SNT 0769, QB/T 2356, GB/T3916, GB/T14344, FZ/T 54001, GB/T 7690.3, ISO2062 and other standards.

[Instrument Features]

1. Adopting a servo control system, it has the advantages of stable speed, wide speed range, and high positioning accuracy. The spacing length and stretching speed can be set arbitrarily.

2. Adopting a double column gantry support structure, the double screw drive can withstand tensile tests on samples up to 50000N. The machine has a simple and beautiful appearance, making it easy for users to distinguish.

3. Different range sensors and testing fixtures can be optionally selected to measure fabrics and monofilaments, with only the need to replace the sensors and fixtures.

4. The software is pre-set with multiple standards, and the device is configured with multiple commonly used standards by default. Users can modify existing standards or customize new standards.

5. Multiple forms of sample fixtures are used in conjunction with various testing functions, with a wide range of applications and diverse testing objects.

6. Force measurement system: Using high-precision sensors, the test data is accurate.

7. Advanced components are used, with fast response speed and high control accuracy, ensuring the stability and accuracy of the product.

8. Display features: During the testing process, the curve is dynamically tracked (monitored), the curve coordinates are automatically scaled (without the intervention of testing personnel), and the report and curve are tracked and displayed simultaneously.

9. The operating software supports customized Chinese Simplified, Traditional, English and other multilingual versions.

10. We can provide various customer services such as software functions, algorithms, reports, statistical analysis, etc. according to customer needs.

11. This machine is directly controlled by a computer through a high-speed port, providing detailed in progress and historical data, report statistics, and establishing a database.

12. The test report can be exported in various file formats such as Excel, Word, PDF, etc., making it convenient for customers to conduct laboratory network comparison and evaluation.

13. Rich report query function, can query reports based on year, month, and day, and can customize report headers.

Instrument performance and main technical parameters

1. Testing method: determined according to the principle of constant elongation (CRE), the entire process is controlled by a computer, and the dynamic changes of the curve, as well as the fracture strength, fracture elongation (elongation), time, frequency, etc., are recorded

2. Test products: lifting straps, ton bags, container bags, seat belts, plastic woven bag base fabrics, plastic monofilaments and other products

3. Range: 10000N/20000N/30000N/50000N (for sling clamps), 3000N/5000N (for fabric clamps), 100N/300N/500N (for single wire clamps)

4. Force measurement accuracy: ± 1%

5. Clamping distance: 50-800mm (different clamping distances can be set for different testing fixtures)

6. Stretching speed: 0.5-500mm/min (infinitely adjustable)

7. Elongation resolution: 0.01mm

8. Fixtures: sling fixture, fabric fixture, monofilament fixture or fabric monofilament combination fixture (configured according to requirements)

9. Print output: Various forms of data, curves, and statistical results including fracture strength, fracture strength, fracture elongation, and fracture time

10. Equipment dimensions: 750mm x 360mm x 1680mm (length x width x height)

11. Packaging size: 900 × 550 × 1880mm (length × width × height)

12. Weight: 300kg

Home

Home About Us

About Us News

News Product Center

Product Center Product catalog

Product catalog After-sale service

After-sale service Download Center

Download Center Customer case

Customer case Talent recruitment

Talent recruitment