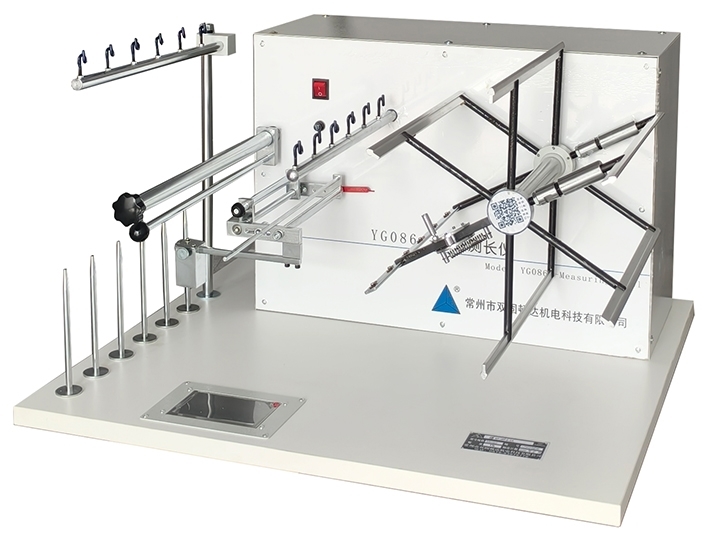

[Scope of Application]

1. The friction coefficient meter is based on the GB 10006 national standard and is specialized in measuring the static and dynamic friction coefficients of materials such as plastic films and sheets, rubber, paper, cardboard, woven bags, fabric styles, metal composite tapes for communication cables and optical cables, conveyor belts, wood, coatings, brake pads, wipers, shoe materials, tires, etc. when sliding. By measuring the smoothness of materials, the production quality and process indicators of materials can be controlled and adjusted to meet the requirements of product use. In addition, it can also be used for measuring the smoothness performance of daily chemical products such as cosmetics and eye drops.

2. Thin films are suitable for testing the static and dynamic friction coefficients of plastic films and thin sheets

3. Paper is suitable for testing the dynamic and static friction coefficients of paper and cardboard

4. Textiles, non-woven fabrics, and woven bags are suitable for the static friction coefficient and dynamic properties of textiles, non-woven fabrics, and woven bags

5. Coefficient testing

6. Rubber is suitable for testing the static and dynamic friction coefficients of rubber

7. Aluminum foil, aluminum foil composite film, and metal products are suitable for testing the static and dynamic friction coefficients of aluminum foil, aluminum foil composite film, and metal products

8. Printed materials, suitable for testing the static and dynamic friction coefficients of printed materials

【 Compliant with standards 】

GGB 10006、GB/T 17200、GB/T22895、ISO 8295、ASTM D1894、TAPPI T816

[Instrument Features]

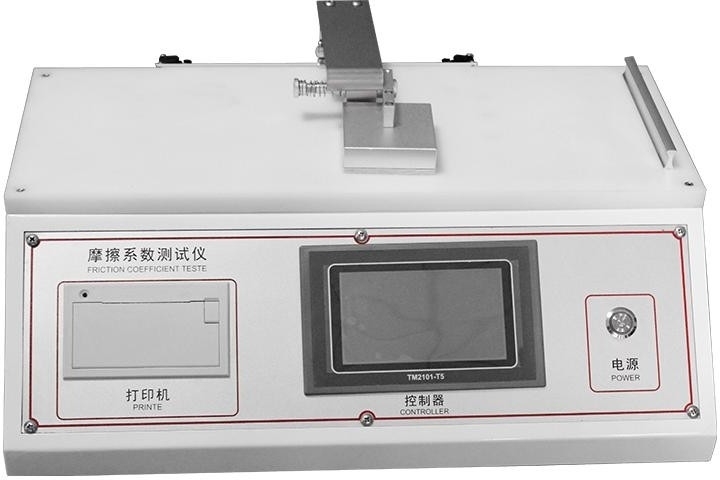

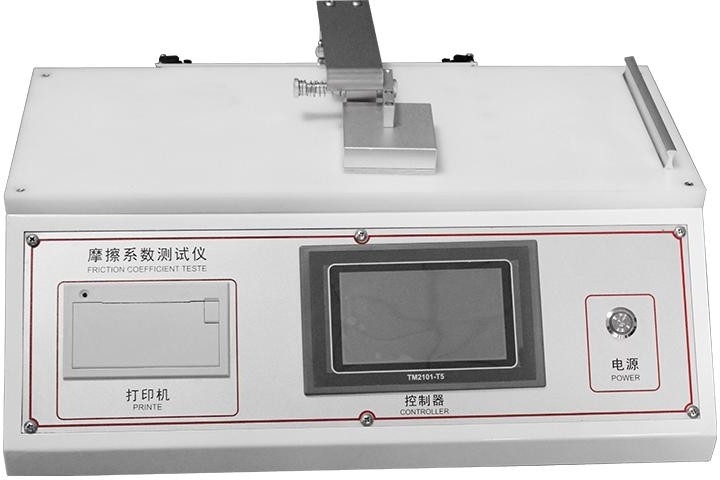

1. The equipment is controlled by a microcomputer, and the testing process is automated. It is equipped with a menu style operating interface, PVC control panel, and LCD display screen, making it convenient for users to perform testing operations and view data.

2. The system accessories are all made of well-known manufacturers' components, with stable and reliable performance. The high-precision force sensor achieves the highest testing accuracy in China: 0.001N

3. No mechanical knob, fully digital system, digital calibration and zeroing

4. The specially designed drive system runs smoothly and produces more accurate test results.

5. The system can simultaneously measure the static friction coefficient and dynamic friction coefficient of the sample.

6. Equipped with a micro printer to automatically print test reports for individual or group samples.

7. The instrument test bench and test slider have undergone demagnetization treatment and residual magnetism detection, effectively reducing system testing errors.

8. Group data, embedded data statistical analysis function.

9. The instrument interface is designed to be simple, easy to operate, and convenient to use.

Main technical parameters

1. Measurement range: 0-5 N

2. Measurement accuracy: 0.001N

3. Slide stroke: 70 mm

4. Slide mass: 200g

5. Test speed: 100mm/min

6. Test conditions: Standard test environment

7. Host size: 400 mm × 300 mm × 200mm (L × B × H)

8. Power supply: AC 220V ± 10% 50Hz

9. Net weight: 20Kg

Home

Home About Us

About Us News

News Product Center

Product Center Product catalog

Product catalog After-sale service

After-sale service Download Center

Download Center Customer case

Customer case Talent recruitment

Talent recruitment