[Product Usage]

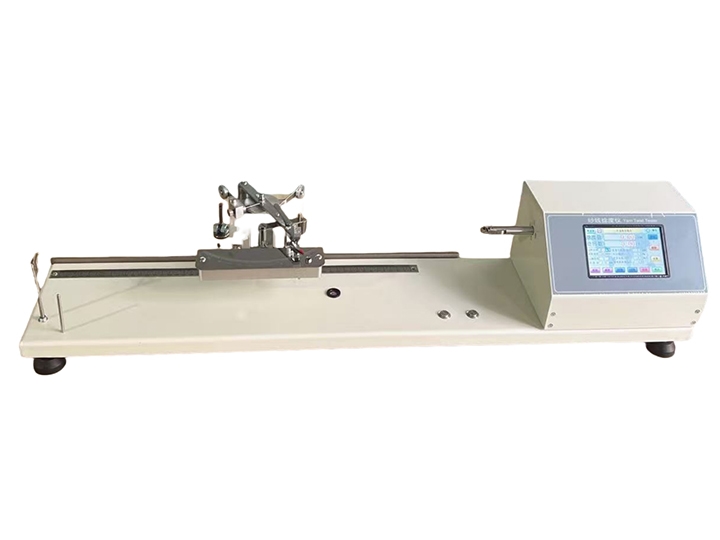

The YG023C-III fully automatic single yarn strength tester is used to automatically measure the breaking strength, breaking elongation, breaking elongation, breaking strength, breaking work, breaking time, CV value, modulus and other physical indicators of various chemical fiber long and deformed yarns such as polyester, nylon, polypropylene, cotton yarn, BCF carpet yarn, sewing thread and other single yarn. The testing software is compatible with mainstream operating systems and supports customized English/Russian and other multilingual versions. It is controlled by a PC to achieve automation of the testing process.

[Applicable Standards]

Chinese standards such as GB/T 14344, GB/T 3916, GB/T 398, FZ/T 54001, ISO2062, ASTM D2256, as well as other national standards.

[Scope of Application]

Suitable for various types of textile enterprises, chemical fiber enterprises, colleges and universities, and inspection institutions at all levels in China, including large, medium, and small

[Instrument Features]

1. This instrument has automatic yarn clamping, automatic yarn shifting, automatic yarn changing, automatic yarn cutting, automatic stretching, automatic alarm, automatic saving of test data and statistical reports.

2.Adopting a 10.4-inch large touch screen operation, the operation is simple, the display is more intuitive, and the experience is good. The touch screen has a built-in 26 key input method in both Chinese and English. The touch screen can directly set the operator name, sample name, batch number, test standard, temperature, humidity, clamping length, stretching speed, pre tension, number of test tubes, test times, linear density, tensile testing unit CN/N and other test parameters. The set test parameters are synchronized with the computer software. After a test is completed, the touch screen will directly display the current number of test tubes, current test times, current fracture strength and other data, and the test can be stopped or paused at any time for more flexible operation.

3.Pre tension adopts automatic loading

4. Users can easily perform daily maintenance or calibration of the instrument based on the manual and touch screen. They can independently calibrate the force sensor, clamping length, stretching speed, and number of yarn rack tubes.

5. Equipped with big data statistical functions, it can generate weekly, monthly, and annual reports, making it convenient for customers to control product quality.

6. This instrument has high testing accuracy, good repeatability, reduces human error, saves labor, and greatly improves work efficiency.

7. The clamping method adopts pneumatic clamping, which does not damage the sample to be tested.

8. Adopting an AC servo system for transmission, with constant torque, smooth transmission, fast speed, and high efficiency.

9. The yarn shifting adopts a stepper motor and a screw, with high positioning accuracy and good repeatability.

10. Using high-precision force sensors, the test data is accurate.

11. The yarn rack can simultaneously hang 20 tubes of samples to be tested, and the movement can be controlled by a stepper motor to exchange for samples.

12. Use pneumatic scissors to cut the current test sample before exchanging it for the next tube of test sample.

13. The robotic arm controls the cylinder through compressed air to achieve its movement and automatically pick up samples.

14. This machine adopts pneumatic upper and lower clamps, which control the movement of the cylinder through compressed air to control the upper and lower clamps, used for clamping and stretching the test sample.

15. This machine is equipped with a waste silk storage box, and during operation, the waste silk will be stored in the storage box through a suction tube.

16. The built-in pressure gauge of this machine can display the compressed air pressure. It is equipped with a pressure regulating valve, which can be pulled out to adjust the compressed air pressure. Pressing the valve in can achieve self-locking.

17. Operating software: Customizable in multiple languages such as Chinese, English, and traditional Chinese.

18. The test report can be exported in various file formats such as Excel, Word, PDF, etc., making it convenient for customers to conduct laboratory network comparison and evaluation.

Main technical parameters of the instrument

1. Measurement principle: Constant elongation type (CRE)

2. Load testing range: 0-5000CN (sensor range can be set to 2500cn, 1000cn, or other ranges can be entered by oneself in the software), 0-100N, 0-300N, 0-500N (optional according to user testing needs)

3. Load measurement accuracy: ± 0.05%

4. Sampling frequency: 1000 Hertz (Hz)

5. Extension measurement range: When the clamping distance is 500mm, the extension range is 0-300mm

6. Clamping distance and accuracy: 100mm-500mm (freely set on software), clamping distance accuracy: ± 1mm

7. Positioning accuracy: ± 0.01mm

8. Pre tension range: 0-500CN (optional range, pre tension is automatically loaded, determined by the product of sample line density (fineness) and pre tension coefficient)

9. Stretching speed range: 0.01mm/min to 15000mm/min

10. Test frequency: over 2000 times

11. Test quantity: 20 consecutive samples can be made at once

12. Clamping method: pneumatic clamping, pressure: (0.4-0.8)Mpa

13. Input methods for various parameters: computer keyboard, mouse input, or touch screen input

14. Test data output method: The output data includes: fracture strength, fracture elongation, fracture strength, fracture time, fracture energy, constant strength elongation, constant elongation strength, as well as the maximum, minimum, average, and CV values in data statistics (can be customized according to customer requirements)

15. Print output: fracture strength, fracture elongation, fracture strength, fracture time, fracture energy, maximum value, minimum value, average value, CV value, and curve graph

16. Equipment dimensions: Maximum dimensions are 1000mm × 530mm × 1770mm (length × width × height)

17. Packaging dimensions: 1980mm x 770mm x 835mm (length x width x height)

18. Weight: 220kg

Home

Home About Us

About Us News

News Product Center

Product Center Product catalog

Product catalog After-sale service

After-sale service Download Center

Download Center Customer case

Customer case Talent recruitment

Talent recruitment