YG026PF industrial yarn strength machine (pneumatic clamp)

Key words:YG026PF industrial yarn strength machine (pneumatic clamp)

Product Description:【Scope of application】YG026PF industrial yarn strength tester (pneumatic clamp) is used to test polyester industrial filament, V-belt and poly-ribbed belt with dipped polyester cord, dipped cord, ultra-high molecular weight polyethylene fiber, aramid fib…

【Scope of application】

YG026PF industrial yarn strength tester (pneumatic clamp) is used to test polyester industrial filament, V-belt and poly-ribbed belt with dipped polyester cord, dipped cord, ultra-high molecular weight polyethylene fiber, aramid fiber (Aramid), carbon fiber and other high-strength chemical fiber filaments (generally refers to filaments with a breaking strength greater than 10cN/dtex) breaking strength and breaking elongation.

【Standards compliant】

GB/T 19975-2005 Test method for tensile properties of high-strength fiber filament

HG/T 2821.2-2012 Dipped polyester cords for V-belts and ribbed belts Part 2: Flexible cords

GB/T 16604-2017 Polyester industrial filament

GB T 32108-2015 Test method for tensile properties of dipped cords, yarns and cords

[Instrument features]

1. It adopts double-pillar gantry bracket structure, beautiful appearance and stable operation.

2. Using high-precision and high-efficiency load cell, the test data is accurate.

3. Controller: computer control, strong anti-interference ability, fast speed, sampling rate ≥1000 times/second, and can process curves and reports at the same time (powerful measurement software is compatible with Windows XP or Windows 7 32-bit operating system).

4. Display features: dynamic tracking (monitoring) of the curve during the test, automatic scaling of the curve coordinates, and simultaneous display of the report and the stretch curve on the test report.

5. Operating software: Chinese, English, Chinese traditional and other multi-language software can be customized.

6. Operating features: easy to operate, you can customize the sample name, batch number, test times, operator name and other information.

7. It can save the test data and results, has the necessary functions such as curve display, query, etc., the test speed is continuously adjustable, the sample is broken and automatically stops, and the upper and lower limit protection functions.

8. It can independently calibrate the force value of the load cell.

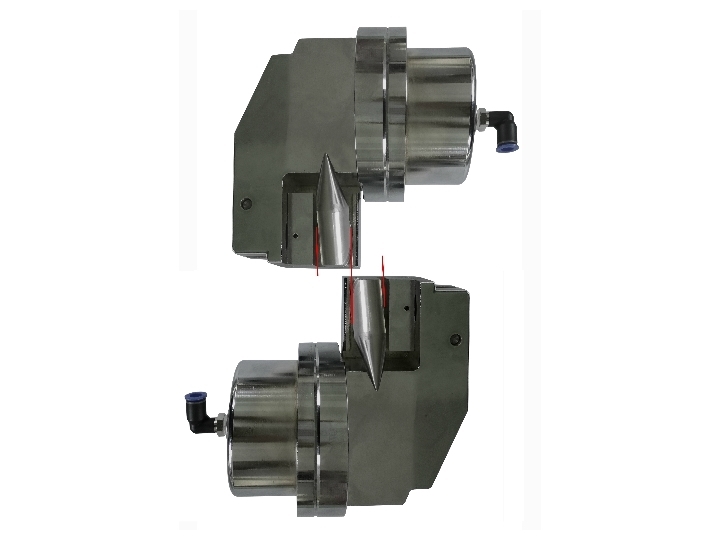

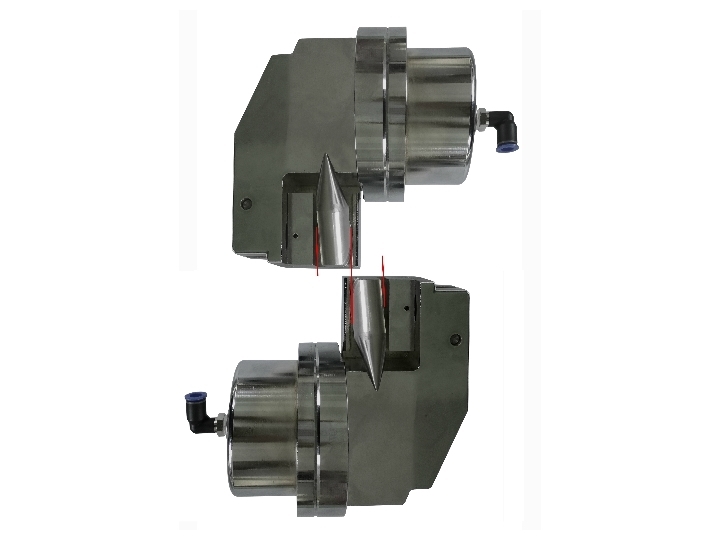

9. Adopt pneumatic industrial wire clamp clamping method.

10. Connect computer software to control machine operation and data processing, generate data reports, curves, etc., for archiving and viewing.

11. Various functions can be customized through software, and it can easily deal with various standard updates and upgrades.

12. The pre-tension is set by the computer software and applied by the tension sensor when clamping the sample (the pre-tension application range is applied according to the standard and linear density).

13. The test report can be exported to Word format, Excel table format, PDF file format and other formats, which is convenient for checking test data at any time.

[Instrument performance and main technical parameters]

1. Test method: CRE principle measurement, computer control, and record dynamic changes of the curve

2. Test products: dipped polyester cords for V-belts and ribbed belts, dipped cords, ultra-high molecular weight polyethylene fibers, aromatic polyamide fibers (aramid), carbon fibers and other high-strength chemical fibers. Silk (generally refers to filament with breaking strength greater than 10cN/dtex)

3. Tension sensor range: 0~100N/200N/300N/500N/3000N/5000N (optional according to user requirements)

4. Force measurement accuracy: <±1%

5. Clamping distance: 150~500mm (arbitrarily set)

6. Accuracy of clamping distance: ±0.01mm

7. Stretching speed: 1~600mm/min (arbitrarily set)

8. Recovery speed: 200mm/min

9. Effective stroke: 600mm (can be customized)

10. Elongation resolution: 0.01mm

11. Print: output various forms of data, curves and statistical results

12. Power source: AC220V±10% 50Hz

13. Equipment dimensions (length×width×height): 820mm×600mm×1600mm

14. Weight: about 220Kg

15. Clamping method: pneumatic industrial wire clamp

Home

Home About Us

About Us News

News Product Center

Product Center Product catalog

Product catalog After-sale service

After-sale service Download Center

Download Center Customer case

Customer case Talent recruitment

Talent recruitment