SG689WF type automatic non-woven spinneret microscopic inspection instrument (detector)

Key words:SG689WF type automatic non-woven spinneret microscopic inspection instrument (detector)

Product Description:Applicable scope of the instrument: This equipment is suitable for the detection of micro-holes of non-woven spinnerets such as meltblown non-woven spinnerets of 1.6 meters, 2.4 meters, and 3.2 meters, and spunbonded non-woven spinnerets (non-standard cust…

Product Details Photo Gallery

Applicable scope of the instrument: This equipment is suitable for the detection of micro-holes of non-woven spinnerets such as meltblown non-woven spinnerets of 1.6 meters, 2.4 meters, and 3.2 meters, and spunbonded non-woven spinnerets (non-standard customized , Can be customized according to customer needs).

Brief description of the instrument:

a.SG689WF type automatic non-woven spinneret mirror inspection instrument is mainly composed of a computer, a motion control system, and an image acquisition system. It can automatically measure the micropores of the non-woven spinneret, which can completely replace manual operation. Really detect the micropores, can detect the hole area of the non-woven spinneret (whether the micropores are blocked), hole area, hole perimeter and other indicators, and carry out detailed measurement of the micropores in each area by area, and test data Can save and print out at any time.

two. Brief Introduction of Automatic Non-woven Spinneret Microscope

① Hardware introduction

1. It adopts a fully automatic X-Y-Z three-axis motion control platform (that is, a three-axis orthogonal robot), and uses a servo motor for positioning, and the repeat positioning accuracy can reach +-0.01mm.

2. The lens adopts imported continuous zoom lens, which has the characteristics of small distortion and high resolution

3. The camera adopts a high frame rate and high resolution camera to ensure that the captured images are not distorted, thereby ensuring measurement accuracy.

4. Use a constant LED light source to ensure that the test environment is not affected by external light sources (the upper and lower light sources are both red light, and black and white cameras are most sensitive to red light).

5. The overall frame adopts a metal frame (the working platform adopts a whole thickened aluminum plate to ensure the flatness of the platform).

6. Equipped with a display for easy observation of the test process and progress (the display can be installed vertically to save space).

7. Use branded computers to ensure the stability of the hardware.

① Software introduction

1. Using a reliable image processing algorithm, it can detect the area and circumference of the micro-holes of the non-woven spinneret (the specific parameters depend on the specific hole type), and automatically identify and clean the unqualified micro-holes.

2. When calibrating the spinneret template file, the coordinates of the holes are automatically collected, which is convenient for operation. The detection sequence of the holes can be customized or the software can automatically complete the optimization arrangement (automatic optimization can reduce the detection path and improve the detection efficiency).

3. The lens realizes auto focus and improves the detection efficiency.

4. It has the function of detecting the parallelism of the lens and the fixture, and the lens and the non-woven spinneret, which is convenient for mechanical debugging.

5. The test data will be saved in the database, and reports can be printed or saved to facilitate data recording and analysis.

6. Improve the efficiency of spinneret microhole detection through optimization of algorithms and paths.

7. When testing different non-woven spinnerets, only need to load different non-woven spinneret template files, which is flexible and convenient.

② Advantages of using this equipment

1. Ensure detection accuracy, avoid missed detection, wrong detection and other human factors, increase product quality, and avoid defective products.

2. Save manpower expenditure. Because the process is fully automatic, one person can complete the inspection of multiple boards. Because it is a mechanical device, it can work continuously for 24 hours, further reducing costs.

3. When purchasing a new non-woven spinneret, its quality can be inspected through this equipment.

4. Master the service life and quality of old non-woven spinnerets.

Please indicate the source(SG689WF type automatic non-woven spinneret microscopic inspection instrument (detector):/companynews/422)

Related articles

Related Products

-

YG815A (vertical method) fabric flame retardant performance tester

-

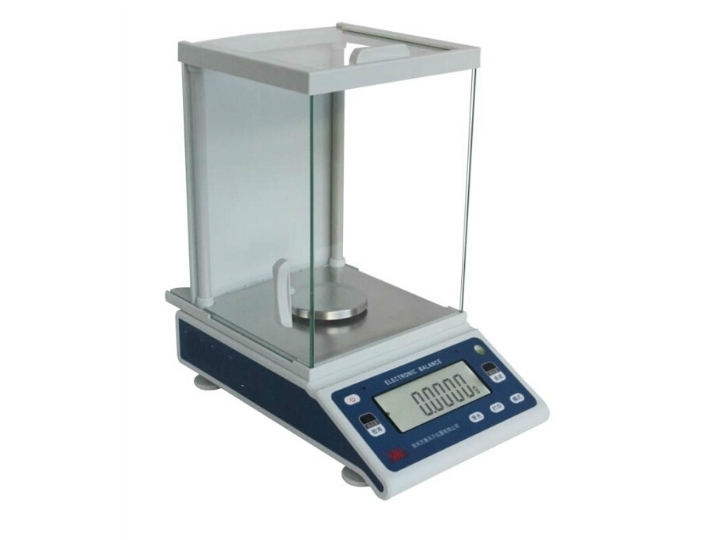

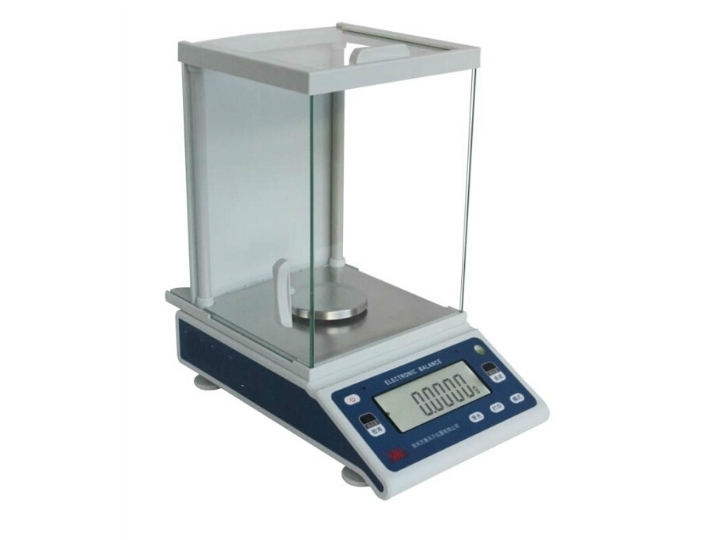

FA1004/2004 type 1/10000 electronic balance

-

WT2003 type one thousandth electronic balance

-

WT1002/2002 One Percent Electronic Balance

-

YG825 fabric hydrostatic pressure tester

-

ZB01B type disc sampler

-

Strength LD-102 hand pressure disc sampler

-

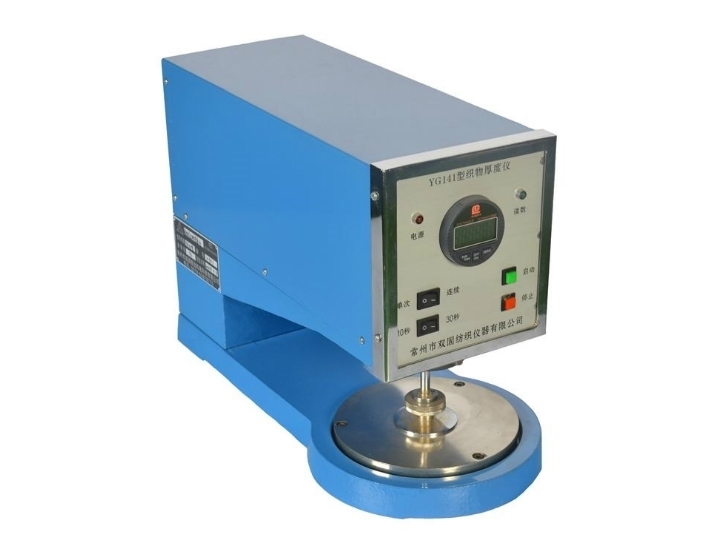

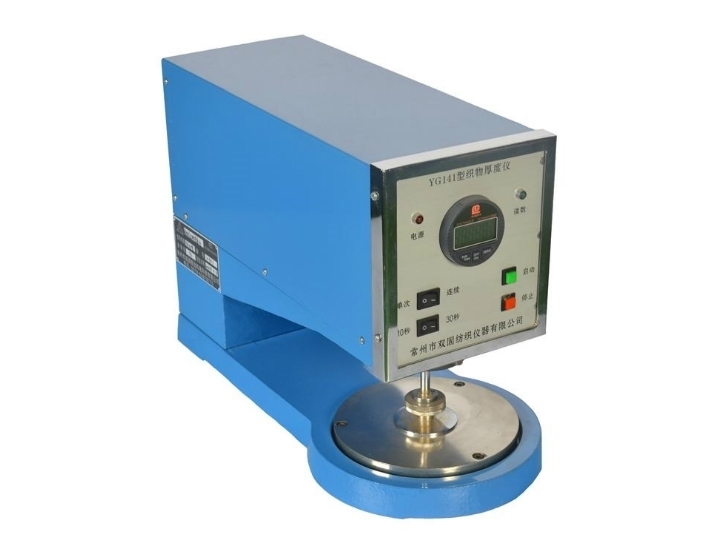

YG141 non-woven fabric thickness tester

-

YG461E fabric air permeability tester

-

SG689WF type automatic non-woven spinneret microscopic inspection instrument (detector)

Home

Home About Us

About Us News

News Product Center

Product Center Product catalog

Product catalog After-sale service

After-sale service Download Center

Download Center Customer case

Customer case Talent recruitment

Talent recruitment